Net Zero GHG Emission Planning

Net Zero GHG Emission Planning

“Net Zero Carbon Emissions – A Dream or an Achievable Goal?”

What is Net Zero Carbon Emissions?

The Net Zero Carbon Emissions concept refers to the zero net Greenhouse Gas (GHG) released to the atmosphere from a given facility when both the emission source (such as from combustion of fuel to generate energy) and sink (e.g., processes to consume CO2 and plantation to absorb CO2 during photosynthesis) are considered.

The concept is proposed to mitigate the impacts of climate change. At the tabling of the 12th Malaysia Plan (RMK-12), the Malaysian Prime Minister, Dato’ Ismail Sabri has declared Malaysia to achieve carbon neutrality (net zero carbon) by 2050. Many western countries and large multinational corporations (e.g., Shell, Petronas, Siemens) have also made committment to achieve Net Zero Carbon Emissions by 2050.

How to reduce GHG emissions?

To reduce GHG emissions, we have to look at the primary sources of GHG emissions. For many organisations, one of the significant sources of emissions comes from the usage of energy, including both electrical and thermal energy usages.

In the context of electricity, GHG emissions are heavily affected by external factors, such as electricity is imported from the grid. The organisation has no control over the type of fuel used in the power plants. In this context, the company has to incorporate Energy Efficiency (EE) initiatives Renewabale Energy (RE) projects such as Solar PV to reduce its reliance on electricity from the grid and to reduce its energy demand. For thermal energy, the organisation may need to undertake EE and RE projects to reduce GHG emissions.

EE Project vs RE Project – which one should be prioritised to Achieve Net Zero Carbon Emissions? A quick look at Carbon Management Hierarchy

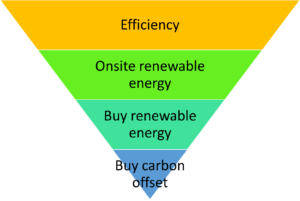

According to the carbon management hierarchy shown in Figure 1, the priority of managing GHG emissions should start by efficiency improvement, followed by onsite generation of renewable energy (RE), purchase of RE, and purchase of carbon offset. This hierarchy is aligned with the energy management hierarchy where the decision-maker should prioritise on energy efficiency over renewable energy projects in order to ensure that the minimum power is consumed before considering other measures.

Figure 1: Carbon Management Hierarchy

⠀

For an RE project, onsite RE generation is preferred over the offsite RE purchase in order to minimise transmission energy loss. Finally, after considering all the above measures, carbon offsets could be considered to reduce the net GHG emissions toward achieving the intended net zero carbon emission goal.

What are the examples of EE projects involving thermal energy?

Improvement of the thermal energy efficiency of an industrial manufacturing site can be done both from the utility system perspective or process perspective.

From the utility system perspective, one can improve the efficiency of the energy supply-side by improving the boiler system efficiency, e.g., optimising the air-fuel ratio, recovering heat from flue gas, cotrolling boiler blowdown, installing a condensate flashing system and incorporating better insulation,. These are the standard options that one organisation can consider. The extent of energy saving depends on the plant current conditions or baseline performance which could be established after conducting the thermal energy audit.

From the process perspective, the possible options include optimisation of key process parameters (e.g., temperature and pressure) and maximising process heat recovery. Without a systematic tool to determine the maximum energy targets, potential improvement areas could be missed. This is how exactly Pinch Analysis can save the day.

Pinch Analysis, enables designers to target and design the maximum heat recovery network for a plant to reduce thermal energy usage and to reduce GHG emissions.

See our published book:

RE project – how to determine the optimise design for RE system?

The energy load profile for every business is different. Therefore, when designing an optimum RE system, there is a need to consider the variation in load profiles across time, availability and intermittency of energy source, and site layout constraints (e.g., space availability). Without a systematic tool, the proposed RE system could be over-designed or under-designed, leading to unnecessary capital and operating expenses.

Our team has developed various tools to cater for aforementioned purposes – read the following articles for more information:

- A new framework for cost-effective design of Hybrid Power Systems

- A Numerical Tool for Integrating Renewable Energy into Total Sites with Variable Supply and Demand

- Total Site Heat Integration planning and design for industrial, urban and renewable systems

- A Numerical Tool for Integrating Renewable Energy into Total Sites with Variable Supply and Demand

How about the case of a larger industry site?

Or a larger scale, we have developed a systematic framework for low CO2 industrial site planning. The Pinch Analysis based framework leverages on Total Site Heat Integration and CO2 Emissions Pinch Analysis coupled with a carbon management hierarchy to maximise CO2 reductions. The proposed tool for low CO2 industrial site planning is available for designers, planners and industrial site owners to optimise integrated energy and CO2 emissions for Total Sites, starting from the individual process units and ready to be extended to Locally Integrated Energy Systems.

See our published articles:

- An integrated Pinch Analysis framework for low CO2 emissions industrial site planning – ScienceDirect

- Holistic carbon planning for industrial parks: a waste-to-resources process integration approach – ScienceDirect

- A framework of resource conservation process integration for eco-industrial site planning

How to achieve Net Zero Carbon Emissions as a company?

There is no “one-size-fits-all” answer for this. Every business is different in terms of operation. For example,

- Lack of space to implement RE project onsite

- The cost of purchasing carbon offset is cheaper than implementing the EE or RE projects

- Purchase RE offsite could be cheaper than EE project due to the economy of scale of larger centralised RE plants at offsite

A systematic approach to design a Net Zero Carbon Emissions Roadmap or Carbon Management Plan is needed for your company to maximise both the monetary saving and GHG emissions reduction.

Contact us to find out how we can help you to achieve this.

Our Approach

Knowing your concerns

We recommend solutions

We deliver based on your parameters

Understanding your position and make informed decision

Knowing your concerns

- Rising electricity and energy bill?

- Lack of information on the energy consumption breakdown for your organisation?

- Not sure what are the most feasible energy saving options for your plants?

We recommend solutions

- Walkthrough audit to identify the low-hanging fruits.

- Site audit for data collection (data logging, inventory checking).

- Conduct interview to access the awareness level of staffs on energy efficiency.

- Use proprietary tool for data analysis and identify the improvement options.

- Reporting the results.

We deliver based on your parameters

- A comprehensive report to visualise the energy consumption profile for your company.

- Understand how the energy (and cost) is being spent via load apportioning.

- Provide you a set of feasible technical solution with different investment category.

Understanding your position and make informed decision

- A comprehensive report of energy consumption profile.

- Understand how the energy (and cost) is being spent via load apportioning.

- Provide feasible technical solution with different investment category.

Updated at September 27, 2021 by Optimal Systems Engineering

Make an Inquiry Here