Energy Audit Service

What is Energy Audit?

An energy audit is a systematic assessment of the baseline energy consumption efficiency within a facility, followed by identification of energy efficiency improvement opportunities and cost-saving measures. Depending on the type of premise, the processes and equipment involved, an energy audit scope may include electrical and thermal energy. An energy audit may be conducted on a whole premise, on a selected, high energy consuming area, or on a specific equipment/system.

Why conduct Energy Audit?

An energy audit is conducted to achieve three key goals, i.e., to assess the energy utilisation performance of a facility, its processes and equipment/system, to reduce energy losses and improve the facility’s energy efficiency, and to reduce the energy bills and improve the profit margin of the affected organisation.

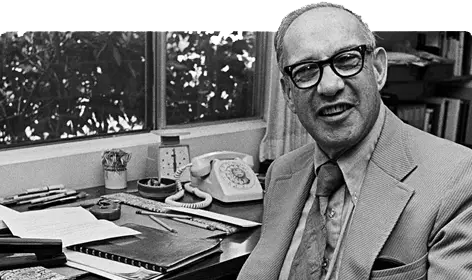

“If you can’t measure it, you can’t improve it.” Peter Drucker.

A well-performed and sufficiently detailed energy audit can provide a company with a clear picture of the overall energy balance and the baseline energy utilisation performance across its facility. As experienced energy auditors, we recommend that preliminary audit is followed by a more detailed energy audit that may involve conducting interviews and discussions with facility owner, gathering information, collecting design and operation data and making parameter measurements to establish the baseline energy balance, identify energy losses and assess the efficiencies and performance of equipment and processes.

Based on the survey findings and analysis, energy auditors typically recommend numerous energy-saving measures that best suit a company. Recommended improvement measures may range from no cost or low cost, medium cost and high-cost investment options. Energy auditors usually estimate the operating cost savings, the required investment, and the payback period (or ROI) for the proposed energy-saving measures.

“I’m glad that I conducted an energy audit. I might have bought a new furnace which would cost a fortune.”

Learn how to identify energy saving opportunities in a process plant through preliminary energy audit.

What are the types of Energy Audit?

There are three types of Energy Audit.

i. Preliminary Energy Audit

Preliminary Energy Audit (PEA) or ‘walk-through audit’ provides an overview of a facility’s current energy scenario. PEA typically involves brief interviews, review of utility bills and operating data, and walk-through of facilities. During PEA, auditors usually identify energy losses through visual observations, apply energy conservation rules-of-thumb, and make quick estimates of potential energy and cost-saving measures. The study may result in a quick recommendation of no-cost and low-cost measures and the need for detailed energy audit analysis based on the walk-through observations.

ii. Detailed Energy Audit

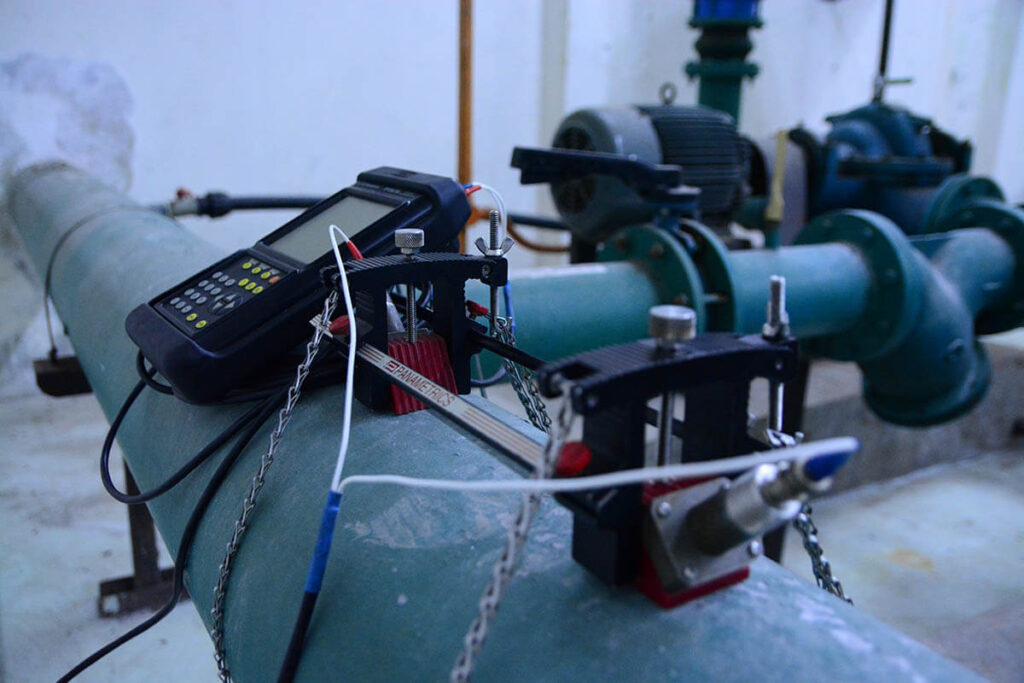

Detailed Energy Audit (DEA) involves a thorough energy balance analysis and evaluation to establish the baseline energy consumption within a facility. DEA typically involves measurement of parameters influencing energy consumption, identifying areas of significant energy users, generating the energy distribution profile of a facility, energy trend analysis, area and equipment energy efficiency analysis, and identifying energy-saving measures (ESMs) and economic analysis of the proposed energy-saving measures. The DEA duration may range between 1 to 10 weeks, depending on the area’s scope and size. The suggestion may include no-cost and low-cost measures, operational changes, modifications to system controls and building automation, and potential capital upgrades. The auditor will provide preliminary economic analysis on the identified energy savings potential, the investment needed, and its payback period for the facility owner to evaluate the ESMs and decide how to proceed with the implementation. If a company is applying for funding, certification, or an award, DEA is typically a major requirement.

iii. Investment-grade Audit

Some recommendations from the ‘Detailed Energy Audit level’ may require significant investment in capital, personnel, and other resources. Before committing to such an investment, the facility owner is recommended to seek expert advice to perform a more thorough cost-benefit feasibility analysis. Examples of investment-grade audits are installing renewable energy systems or a combined heat and power system (cogeneration).

Who should conduct Energy Audit?

An energy audit can help a company save energy cost, improve profitability, project a positive image and ultimately gain a competitive edge. Conducting an energy audit can therefore benefit any company, especially the large energy consumers.

In Malaysia, companies consuming both electrical and thermal energy equal to or more than 21,600 GJ a year must comply with the Energy Efficiency and Conservation Act (EECA 2024). Under the EECA 2024, the energy consumer must:

- Appoint a Registered Energy Manager (REM)

- Develop energy management systems (EMS)

- Conduct an energy audit every five years

- Submit Energy Efficiency Conservation Report (EECR) yearly

Under the EECA 2024, energy consumer needs to conduct energy audit every five years. The findings and recommendations from the energy audits can be used as a basis for a company to implement a sustainable energy management system (EMS) improvement program. The required regular reporting of such energy management program can, in turn, help the company abide by the Energy Commission requirement to submit energy consumption report every six months.

Companies wishing to sustain the benefits of implementing good energy management practices and gain international recognition may apply for the Energy Management System (EMS) Certification under ISO50001 or AEMAS Energy Management Gold Standard. After establishing a good energy management program, companies are recommended to embark on a benchmarking exercise by participating in energy awards program such as the National Energy Award (NEA) and the ASEAN Energy Award. All in all, conducting periodic energy audit can go a long way in helping companies abide by EECA 2024, comply with EMS certification requirement, formulate an action plan to implement energy-saving measures and energy management best practices, and pave the way for a company to craft its competitive edge by winning energy awards.

Learn more about various Energy Awards.

Is there any government support for Energy Audit in Malaysia?

The good news is, YES!

In the recent 2021 budget announcement, the government has approved the Energy Audit Conditional Grant (EACG) extension to support energy audit to be conducted for the commercial and industrial sectors up to 2025. The EACG is applicable for designated companies with energy consumption more than 100,000 kWh per month. Companies interested in applying for EACG must do so in partnership with an Energy Service Company (ESCO) registered under Suruhanjaya Tenaga. The grant supports the cost of the Energy Audit (please refer to the terms and reference). If you are interested in applying for EACG, please contact us. We shall be happy to work with you and guide you through the process!

Where to find Certified Energy Auditor Services Company?

Optimal Systems Engineering Sdn Bhd (OPTIMISE) is a registered energy service company (ESCO) under the Energy Commission with over three decades’ experience as energy auditor and energy management systems consultant. OPTIMISE consultants are Certified Energy Auditor (CEA), Thermal Energy Recovery Technologist (TERT) Practitioner, Accredited Energy Measurement & Verification Professional (AEMVP), Country Expert Steam System Optimisation, Registered Energy Manager Type 2, Certified Energy Manager and ISO50001 Lead Auditor.

OPTIMISE services cover energy and resource sustainability:

1. Energy Audit

2. Energy Management System (EECA 2024, ISO50001, AEMAS EMGS)

4. Pinch Analysis (maximum energy recovery analysis or heat recovery optimisation)

5. Measurement and Verification (M&V)

Contact us for more details on the services.

Detailed Energy Audit (Add-on)

Maximising your site energy recovery using ‘Pinch Technology‘.

“I have always thought that energy audit to improve utility systems efficiency involving boilers and chillers is the only way to reduce my thermal energy bills. Now I know that utility audit is only the tip of the ice-berg.

Utility boilers/furnaces constitute the energy supply side that provides heat to satisfy process energy demand-side consisting of units as reactors, kilns, separators, evaporators, dryers, heat exchanger network, heaters, coolers and refrigeration systems. Over time, demand for energy supply from boilers/furnaces of a manufacturing site will typically rise due to inefficiencies and aging equipment. The bulk of rising demand for more heat from boilers typically originates at the core of the process, i.e. at the reactor, followed by a separator, process heaters, and heat exchangers. If energy audit and heat recovery are concentrated on the boiler (supply side), a significantly larger energy-saving opportunity at the demand side can be lost. Therefore, the process (demand side) needs to be thoroughly audited so that potential energy recovery and efficiency improvement opportunities shall not be missed.

Pinch Analysis (PA) is a systematic tool to maximise thermal energy and resource efficiency through maximum waste heat and resource recovery. Over 7,000 successful Pinch Analysis applications worldwide, including our project experiences show that pinch analysis applications led to potentialthermal energy and utility cost savings of between 10 to 60%, and payback periods of less than three years. One of our recent petroleum refinery retrofit project, for example, amassed an annual saving of USD 12 Million.

Learn the bigger picture to maximise energy savings here.

When a Pinch Analysis study was conducted on my site, they delved deep into the core of the process. They managed to reduce the demands for utility heating and cooling significantly. This had resulted in a boiler being decommissioned instead! Can you imagine how much cost saving that is!”

Detailed Energy Audit (Add-on): Solar Thermal Integration

Is your company using electricity or fuel to generate low-grade heat such as hot water or low-pressure steam? If yes, then your company could be a great candidate to install and implement a solar thermal energy system. With a solar thermal energy system, you can harness free and clean energy from the sun to generate hot water for your facilities.

Our team has expertise in designing an optimal solar thermal energy system for your facilities. Unlike the other solution provider, we shall first study the overall energy flow of your facilities, and examine the possible heat recovery scheme within existing processes using Pinch Analysis, before resorting to Solar Thermal Project, which typically requires higher investment.

“ Installing solar thermal system without conducting Pinch Analysis is like supplying water through a pipe with a leaking hose. Without first maximising energy efficiency at the core of the process, most of the supplied energy could go to waste.”

Our Approach

Knowing your concerns

We recommend solutions

We deliver based on your parameters

Understanding your position and make informed decision

Knowing your concerns

- Rising electricity and energy bill?

- Lack of information on the energy consumption breakdown for your organisation?

- Not sure what are the most feasible energy saving options for your plants?

We recommend solutions

- Walkthrough audit to identify the low-hanging fruits.

- Site audit for data collection (data logging, inventory checking).

- Conduct interview to access the awareness level of staffs on energy efficiency.

- Use proprietary tool for data analysis and identify the improvement options.

- Reporting the results.

We deliver based on your parameters

- A comprehensive report to visualise the energy consumption profile for your company.

- Understand how the energy (and cost) is being spent via load apportioning.

- Provide you a set of feasible technical solution with different investment category.

Understanding your position and make informed decision

- A comprehensive report of energy consumption profile.

- Understand how the energy (and cost) is being spent via load apportioning.

- Provide feasible technical solution with different investment category.

Updated at May 3, 2020 by Optimal Systems Engineering