Real-Time, Energy-Efficient Operation with RENKEI Optimal Control

In Article, Latest News

26th February 2024

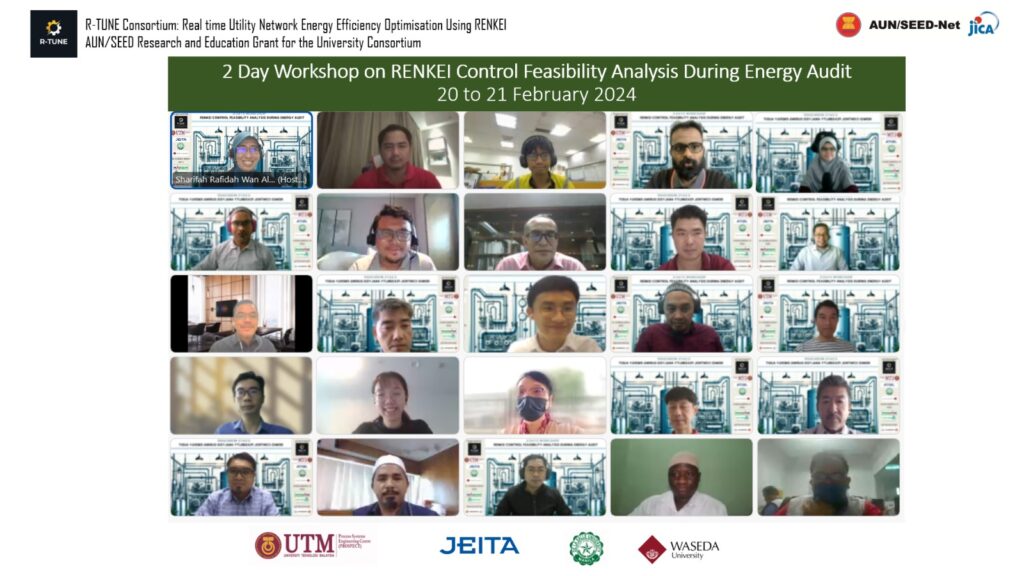

22 February 2024 – More than 50 energy professionals from across ASEAN attended the 2-Days Workshop on Using RENKEI Control for Energy Audit on 20 and 21 February 2024.

Organised by the ASEAN Real-Time Utility Network Energy Efficiency Using RENKEI (R-TUNE) Consortium which comprises Universiti Teknologi Malaysia (UTM), the Japan Electronics and Information Technology Industries Association (JEITA), Waseda University of Japan, De La Salle University of the Philippines, and in collaboration with Optimal Systems Engineering (OPTIMISE) and Malaysian Association of Registered Electrical Energy Managers (MAREEM), the workshop aimed to build capacity on the RENKEI Control technology for energy auditors, energy managers and energy service companies (ESCOs) across ASEAN.

Professor Ir Ts Dr Sharifah Rafidah Wan Alwi who heads the consortium said that R-TUNE is a project sponsored by AUN/SEED.net under the Research and Education Consortium Grant (RED-UC).

According to her, R-TUNE has developed an innovative assessment tool to help industries analyse the potential for applying RENKEI Control on boilers, turbines, air compressors and chillers in their facilities. The team has also developed P-Graph models for energy auditors to evaluate the potential energy savings for boilers and turbines when used together with RENKEI Control analysis.

As an industrial practitioner, an ASEAN-certified energy manager and a Registered Electrical Energy Manager (REEM) under the Malaysia Energy Commission, Prof Sharifah shared that, “typical energy conservation measures may range from no cost and low-cost measures such as preventive maintenance and simple adjustment of equipment parameters, to high-cost measures such as replacement of older equipment such as pumps, compressors and chillers with more energy-efficient ones”.

According to her, “RENKEI Control, on the other hand, is a data-driven energy digitalisation tool that enables energy end users to achieve cost-effective real-time energy efficiency and GHG emission reduction by prioritising the use of the existing higher efficiency equipment through optimal control, thereby avoiding unnecessary and premature equipment replacement.”

Prof Sharifah added that, “In light of the anticipated Energy Efficiency Conservation Act (EECA), organisations can consider RENKEI Control as one of the high- potential energy saving and emission reduction measures during an energy audit.”

Her thoughts were largely echoed by the workshop participants who generally appreciated the new insights they learnt from the 4IR-driven technology during the 2-Days training, as highlighted below:

“This workshop truly opened my eyes to the ways modern technology can aid in assessing and implementing energy-saving measures, particularly for systems like chillers, compressors, boilers, and turbines. It has significantly enhanced my understanding and contributed immensely to my knowledge in this field.”

“Attending the workshop on RENKEI Control Feasibility Analysis During Energy Audits was an incredibly enriching experience. The comprehensive coverage of RENKEI control systems and integration into energy audits provided valuable insights into optimizing energy efficiency in our organization”.

“It is a good opportunity for an existing company/ factory to capitalized on the assessment tools to ensure future operation saving & emission compliance.”

This article is published on 26th February 2024 by Optimal System Engineering